Project Results

I talked to a reporter for BuiltIn recently about this project! Check out her story here - https://builtin.com/3d-printing/3d-printed-meat

About This Project

We want to make the perfect steak, without slaughtering cows.

Ask the Scientists

Join The DiscussionWhat is the context of this research?

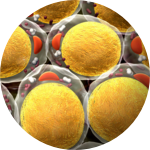

The current factory farm supply chain for meat is unsustainable; it cannot meet the global population’s ever-increasing demand for animal proteins. One option is to replace conventionally-produced meat with cultured tissues grown entirely in the lab. Cultured meat can vastly reduce environmental, public health, and food security issues posed by factory farming. To make cultured meat a feasible replacement for conventional meat sources some major technological and consumer-acceptance barriers must be overcome. Currently cultured meat is being processed as ground meat. We propose 3D printing Wagyu beef, which is among the most sought-after meats in the world. This beef is known for its unique fat marbling structure, which creates a buttery tenderness unlike any other meat product.

What is the significance of this project?

Cultured meat is still its infancy stage, where the public perception can make or break the initiative. We are starting with a high-end meat product to attract attention to the capability of these techniques, with the ultimate goal of increasing positive public perception of cultured meat. If adopted, cultured meat would decrease the livestock population thereby improve our current agroecosystem structure. Livestock populations currently consume >25% of global fresh water, 70% of agricultural land, and are responsible for 18% of global anthropogenic greenhouse gas emissions. Furthermore, 3D printing meat would avoid the cruel overfeeding practices required to produce highly marbled meat, making it more accessible to the general public.

What are the goals of the project?

As a proof of concept that delicious cultured meat can be produced in the lab, our goal is to demonstrate the feasibility of printing a high-end meat product without sacrificing an animal. To do this, we will design an optimal cut of meat based on image analysis studies of Wagyu. Using techniques developed in the Feinberg lab to print a full-size human heart with alginate, we will use FRESH 3D printing to print the Wagyu meat. We will use the same alginate bioink used in previous studies, which is an inexpensive material made from seaweed that has material and mechanical properties similar to muscle tissue. We will grow bovine cell lines of adipocytes and myocytes in large quantities to 3D print into the shape. Finally, we will print a full steak, which we will characterize and taste!

Budget

This is the first step in developing a research program around this idea. We need funding to get preliminary data to apply for larger grants to support the research! In particular, we need a dedicated 3D printer to validate our CAD files and to print our final cell-containing product. We also need supplies to grow the cells and to characterize our steak once it is printed.

Endorsed by

Project Timeline

Project Timeline

We will perform image analysis studies (fat/muscle segmentation) of Wagyu to inform our CAD design. Then we will use dyed alginate bioinks to print “muscle” and “fat” regions to optimize printing parameters to ensure that we are printing the marble appearance accurately. Once our printing parameters are validated, we will grow bovine cell lines of adipocytes and myocytes in large quantities to 3D print into the shape. Finally, we will print a full steak for characterization and cooking/tasting.

Mar 01, 2021

Image analysis and 3D reconstruction. Images will be sourced from the internet to recreate fat content and marble structure in CAD models for 3D printing.

Jan 03, 2022

Project Launched

Jun 01, 2022

Validate print parameters with dyed alginate bioinks to print “muscle” and “fat” regions accurately

Oct 01, 2022

Grow bovine cell lines of adipocytes and myocytes in large quantities to 3D print into the shape

Dec 01, 2022

Print a full steak. We will characterize and taste the product (after cooking!) and disseminate all of our findings to news outlets, social media, and a peer-reviewed journal.

Meet the Team

Team Bio

A fat expert (Abbott) and the lab that just 3D printed a human heart (Feinberg) team up to print a steak without sacrificing a cow. Leading the experimental plans is Lindsey Huff, a Master's student passionate about cellular agriculture.

Rosalyn D. Abbott

Dr. Abbott is an Assistant Professor in Biomedical Engineering with a courtesy appointment in Materials Science and Engineering at Carnegie Mellon University. Dr. Abbott received her B.S. and M.S. degrees in Biomedical Engineering from Rensselear Polytechnic Institute and her Ph.D. degree in Bioengineering from the University of Vermont. She was subsequently a postdoctoral fellow in the Biomedical Engineering Department at Tufts University working under the supervision of Professor David Kaplan, were she developed adipose tissue engineered models. Her lab at CMU focuses on adipose tissue engineering to study disease progression (obesity, type II diabetes), regenerative science, and incorporation into cellular agriculture products!

Lindsey Huff

Ms. Huff is a first year PhD student at Carnegie Mellon University in the Department of Biomedical Engineering and is currently working in Dr. Abbott's lab. Ms. Huff graduated from Bradley University in 2021 with a bachelors degree in mechanical engineering with a concentration in biomedical engineering. Her interest include creating an innovative, sustainable, and cruelty-free method to produce meat.

Adam W Feinberg

Dr. Feinberg earned a BS in Materials Science and Engineering from Cornell University in 1999, followed by a Masters (2002) and Ph.D. (2004) in Biomedical Engineering from the University of Florida, where his doctoral work was focused on engineering cell-material interactions to prevent and enhance adhesion. He was then a Postdoctoral Fellow at Harvard University from 2005 to 2010, where he developed new biomaterials and cardiac tissue engineering strategies for 3-dimensional myocardial regeneration, with a focus on stem cell-based approaches. Dr. Feinberg joined CMU in the fall of 2010 as an Assistant Professor with joint appointments in Biomedical Engineering and Materials Science and Engineering. He is a leader in the field on bioprinting and invented the FRESH 3D printing technique which he recently used to print an anatomically correct human heart.

Additional Information

All of our results will be published in a peer-reviewed journal and disseminated across news outlets and social media. CAD files and protocols will be published in open access forums.

Project Backers

- 68Backers

- 101%Funded

- $10,100Total Donations

- $148.53Average Donation