Project Results

I am so excited that the outcome of the research has been published a peer-reviewed paper in a top-tier journal. It brings a new knowledge of science to the community regarding the multiphysics simulation of acoustic emissions as well as the experimental measurements.

About This Project

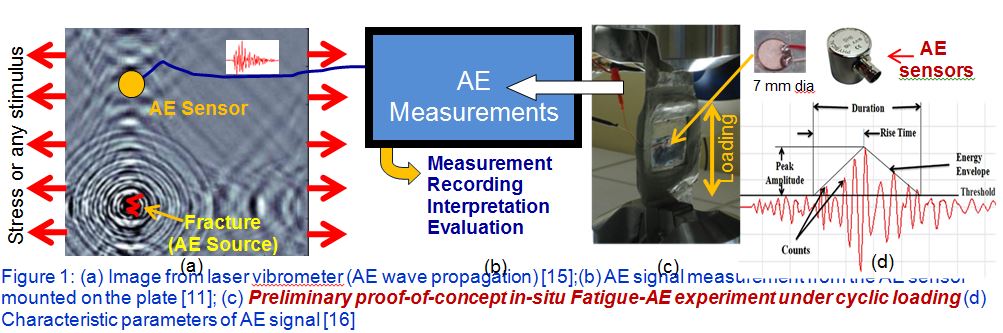

Engineering structures have a damage monitoring system for safe and reliable performance. This project proposes an experimental and multiphysics simulation of a novel Acoustic Emission (AE) technique for damage monitoring in these structures. While the conventional methods do a delayed monitoring and use many actuators, AE monitoring gives the real-time damage information without any actuator. Thus, AE provides precise damage monitoring and saves the cost and power consumption of the actuators.

Ask the Scientists

Join The DiscussionWhat is the context of this research?

This project will address the research question: “Can acoustic emissions tell us the damage state at safety-critical situations on an engineering structure?”

A new and innovative approach to assessing the state of the modern structures efficiently and inexpensively is the key of Structural Health Monitoring (SHM). The acoustic emission (AE) is a rapid release of stress waves from any material state change in the structure. Conventional methods use excitation sources called actuators to assess the damage state in a structure. This novel approach would use acoustic emissions from the structure for diagnosis and prognosis without any actuators; thus, it could save the associated cost, power consumption and complex circuit requirement of the external sources/actuators.

What is the significance of this project?

The US spends more than $200 billion each year for the maintenance of bridge structures, plant equipment and facilities. This novel AE technology could directly be applied to the monitoring of large structures like bridges, aircrafts, high-rise buildings inexpensively, but efficiently. The proper and efficient detection of damage makes the structures safer for the public. In this project, the feasibility of this AE technology will be studied by performing experiments and multiphysics simulations. This is a low cost and less complicated technique than conventional methods. A quantitative criteria for AE sensing will provide efficient diagnosis and prognosis of structural damage.

What are the goals of the project?

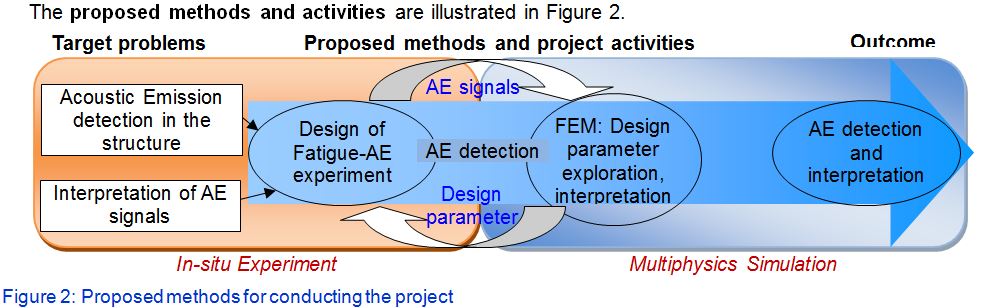

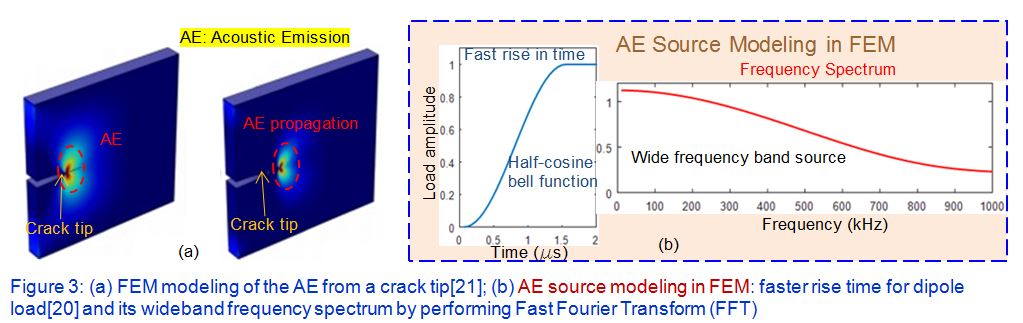

An in-situ AE-fatigue experiment will be designed to "listen to the crack" by the measurement of acoustic emissions. These emissions will be used to find the critical length of the crack that will lead the catastrophic failure of the structure. Aircraft-grade aluminum material will be used to make the samples for the experiment. Fatigue loading, commonly encountered in practice, for engineering structures will be applied to the samples. The multiphysics simulation will provide the optimum positions of the AE sensors used in the experiments, help to interpret the AE signals and understand the structural communication. Thus, a combination of efficient experiment and simulation for better AE sensing is the main goal of this project.

Budget

I am a graduate student experienced in operating MTS fatigue testing machine and conducting FEM simulation with proper background knowledge in this field. I will be working 5 hrs/wk for 12 months to complete the project. Using a standard rate of USC, the salary becomes $4110.

A 48"x48"x0.04 aluminum Al 2024 plate costs $167.94 deom Mcmaster.com; One resonant, three PWAS AE sensors cost $162.06 from PhysicalAcoustics.com. With shipping fee, total=$390.

To share my ideas and results with the professionals, I will be attending the 44th International Conference on Quantitative Non Destructive Evaluation 2017 at Provo, UT. Travel costs of $500 are requested.

Endorsed by

Project Timeline

Project Timeline

Apr 04, 2017

Project Launched

Apr 30, 2017

Study & Design of the experiment

May 31, 2017

Conduct preliminary in-situ experiment

Jun 30, 2017

Multiphysics simulations

Aug 31, 2017

Updating design parameters of experiments and conduct experiments

Meet the Team

Affiliates

Md Yeasin Bhuiyan

I am a PhD graduate student of the mechanical engineering department of University of South Carolina, Columbia, SC.

I also have a master degree in Aerospace Engineering from the University of South Carolina. I am so passionate to discover a new technology for the new generation of the world.

I want to discover a technology that will make an engineering structure safer for the public. I have been working in the field of nondestructive evaluation and structural health monitoring technology for more than four years. These technology primarily inspect the safety condition of the aircrafts, bridges, buildings, and other mega-structures so that the public can use them without having any injury.

I have strong academic background with straight "A" in all semesters. I have research experience with six published journal papers and six international conference papers.

I am confident on my ability to discover a technology that would make the world safer.

Please find the detail of my biography in the following link:

Additional Information

https://drive.google.com/file/...The full description of the proposal can be found in this link.

I uploaded my full proposal in the goggle drive

Project Backers

- 16Backers

- 100%Funded

- $5,001Total Donations

- $166.73Average Donation